Calibration Package

Annual verification of the calibration of the IQT’s instrumentation is recommended to ensure that the IQT’s ignition delay measurements remain accurate, precise and repeatable. Instrumentation that hasn’t been calibrated regularly, or fails to meet calibration requirements, can result in difficulties such as inaccurate test results, or loss of ISO 17025 accreditation for your laboratory’s IQT.

Since the IQT is serviceable in the field, the user has the choice of hiring a fully trained CFR technical service representative or performing the service themselves, after CFR training at its laboratory facilities in Ottawa ON Canada. In order to make the process of instrumentation calibration as simple and convenient as possible for IQT users, CFR Engines Canada has three different instrumentation calibration kits available:

Data Acquisition Board Calibration Kit

Thermocouple Verification Package

Pressure Sensor Calibration Kit

These calibration kits are all compact, cost-effective, purpose-built alternatives to larger, more costly general-purpose instrumentation calibration equipment.

Data Acquisition Board Calibration Kit

As part of the routine annual maintenance of the IQT, the IQT’s user is expected to verify the calibration of the data acquisition board and adjust the settings if necessary. Since all the signals from the IQT’s instrumentation are connected to the data acquisition board, accurate measurements are only possible if it is properly calibrated. CFR Engines Canada’s Customer Kit for Data Acquisition Board Calibration provides a simple and convenient method of performing this calibration procedure.

The Customer Kit for Data Acquisition Board Calibration includes two components:

- A calibration adapter with a precision +5 V reference voltage circuit

- A calibrated, NIST-traceable, high-precision, handheld digital multi-meter (DMM)

- A calibration sheet, valid for one year from the date of issue, is included

Thermocouple Verification Kit

Precise operation of the IQT depends on accurate and repeatable measurement of the instrument’s critical temperatures. The fuel injection pump, combustion chamber pressure sensor and injector nozzle coolant passage temperatures have the greatest effect on IQT accuracy. To ensure that these temperatures are within their required operating limits, the temperature readings must be verified using known temperature references. CFR Engines Canada’s Thermocouple Verification Kit provides a simple and convenient source of known temperature references, for use with these three temperature readings.

The Thermocouple Verification Kit includes four components:

- An electrically heated aluminium isothermal block (100-240 V, 50/60 Hz)

- An unheated aluminium isothermal block

- A precision resistance temperature detector (RTD) probe

- A calibrated, NIST-traceable, hand-held digital RTD thermometer

- A calibration sheet, valid for one year from the date of issue, is included

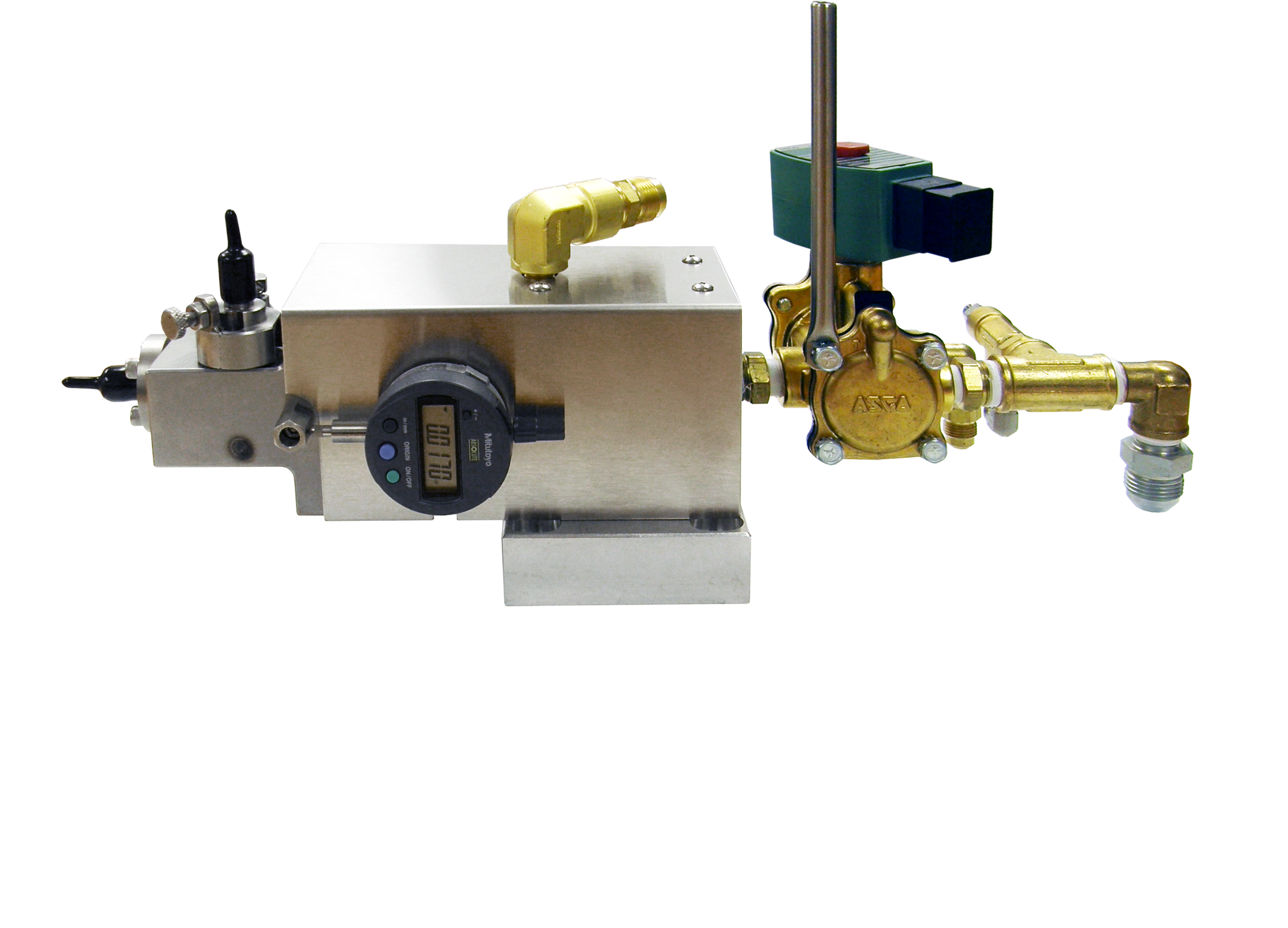

Pressure Sensor Calibration Kit

Precise operation of the IQT also depends on accurate and repeatable measurement of the charge and injection actuator air pressures. To ensure that these pressures are within their required operating limits, the calibration of the charge and injection actuator air pressure sensors must be verified annually. CFR Engines Canada’s Pressure Sensor Calibration Kit provides a simple and convenient method of performing this calibration procedure.

The Pressure Sensor Calibration Kit includes three components:

- A calibrated, NIST-traceable, high-precision, digital reference pressure gauge

- A calibration sheet, valid for one year from the date of issue, is included

- An NPT to Swagelok compression fitting tee adapter

- A right-angle extension tube

The tee adapter and right-angle extension tube allow the digital reference pressure gauge to be connected into the IQT’s gas supply tubing, allowing the existing gas supply system to act as the reference pressure for calibrating the charge and injection actuator air pressure sensors.

| IQT Dimensions | 173cm (68 in) H X 106 cm (41.5 in) W X 73 cm (28.5 in) D. |

| Power Requirement | 20A, 240VAC, 50/60 Hz Protected by an Uninterruptable Power Supply (UPS) and isolation transformer |

| Air Supply | Compressed air, 20.9 % O2 ± 1.0% Regulated: 21.7 bar (310 psi) – Combustion process 12.1 bar (175 psi) – Injection process |

| Nitrogen Supply | Compressed nitrogen, industrial grade Regulated: 3.5 bar (50 psi) – Fuel feed process |

| Cooling System | Closed-circuit liquid to air cooling system |

| Fuel Injection System (Patent Pending) | Pintle-type, single hole nozzle with pneumatically actuated fuel injection pump |

| Computer and Instrument Control | Rack mount computer system with automatic software backup and hot-swappable drives |

Accessories

Accessories