- IQT®-TALM

View more IQT®-TALM

IQT®-TALM The IQT TALM is the most automated and precise IQT system

- IQT®-LM

View more IQT®-LM

IQT®-LM The IQT LM provides excellent precision and value

- Research

View more Research

Research Options for complete test control and full research flexibility

- Accessories

View more Accessories

Accessories Tools and equipment to help ensure successful IQT operation

▲

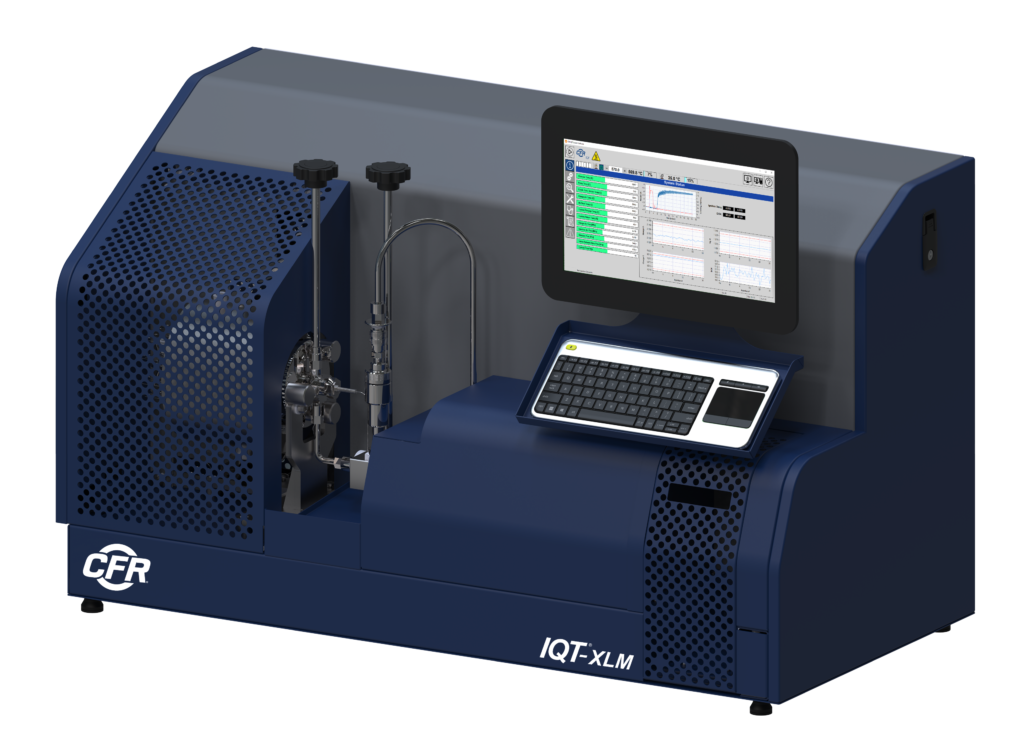

IQT®-XLM Model

The CFR Engines Inc. (CFR®) IQT® Constant Volume Combustion Chamber (CVCC) instrument was introduced to the petroleum industry in 1998.

Since then, the IQT has provided decades of reliable service to refineries and test laboratories for diesel fuel certification and quality control monitoring.

The next generation of IQT, the IQT-XLM, provides the capabilities of the traditional IQT-LM and IQT-TALM models (with an enhanced user experience) in a single more compact, benchtop package or wheeled cart.

Compliance

The IQT conducts tests that are fully compliant with all procedures of the current IQT test methods:

ASTM D6890

EN 15195

IP 498

Cetane measurements for certification purposes meet the requirements of most international and national fuel specifications for diesel fuel, biodiesel blends, HVO and GTL, including:

ASTM D975, ASTM D6751, ASTM D7467

CARB

EN 590, EN 15940

CAN/CGSB-3.517, CAN/CGSB-3.520 , CAN/CGSB-3.522, CAN/CGSB-3.524

- Rapid test results: less than 20 minutes per sample

- Suitable for 24/7 operation

- Automated control of injection nozzle and combustion sensor temperatures (formerly requiring the TALM option) is standard equipment

- Touchscreen-compatible user interface with multi-language capability

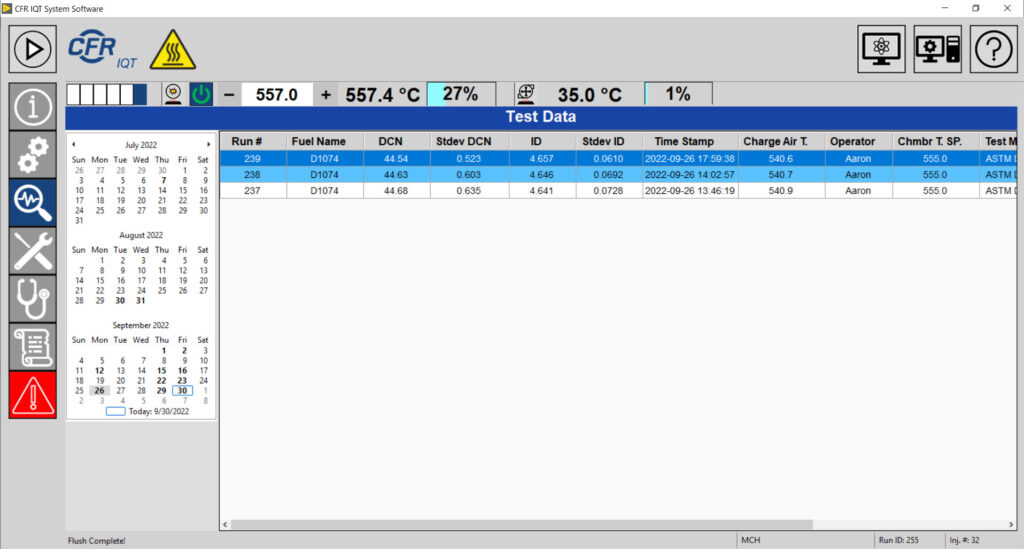

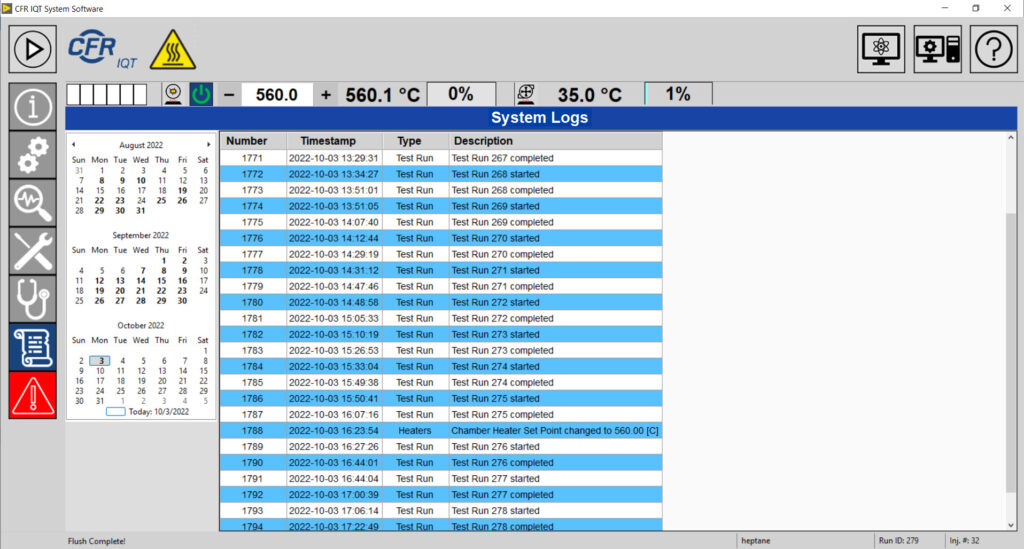

- Access to test records and system logs

- Simplified exhaust ventilation requirements

- Integral sample waste collection system

- Positive pressure cabinet ventilation prevents any ingress of flammable vapors

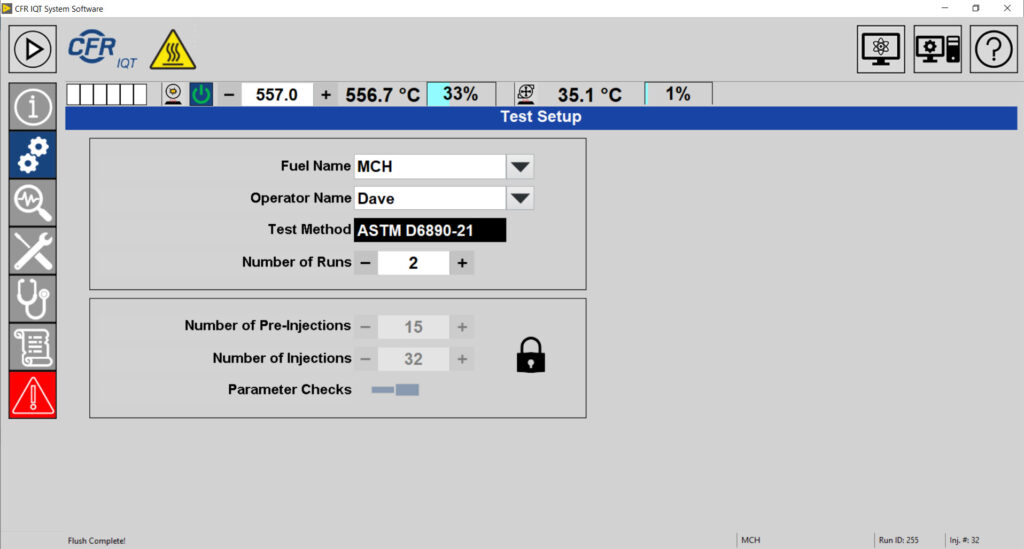

IQT®-XLM Software

The main system operating screen clearly displays all operating parameters, using large, color-coded bar graphs to indicate to the user whether a parameter is within allowable limits. The bar graphs are sized so that a basic check of the instrument’s condition and test progress can be done from a distance.

New intuitive and convenient user interface with:

- Simplified access to calibration and diagnostic functions

- Advanced diagnostics for condition-based maintenance

- Multiple language capabilities

Features

- Touch screen HMI with industrial PC

- Windows® based user interface with full Windows desktop

- Electrical Connection: 20A,208-240 VAC, 50/60Hz

- Integral cooling system with built-in Uninterruptible Power Supply (UPS): > 3.5 hrs of run time for the cooling system and computer

- Low Sample Volume: 35 ml for cleaning, 30 ml for test run

Measurement Results

Ignition delay (ms) and Derived Cetane Number (DCN), Correlation of DCN and Cetane Number (CN) recognized by ASTM (versus D613) and CEN (versus ISO 5165)

Repeatability

- 0.53 @ 40 DCN

- 0.65 @ 50 DCN

- 0.89 @ 70 DCN (ASTM D6890-22)

Derived Cetane Number Range

- 31.5 to 75.1 DCN (ASTM D6890 – 22 scope)

- 30.4 to 78.9 DCN (applicability of ASTM D6890 precision functions per ASTM D6300)

- 33.9 to 76.8 DCN (EN 15195:2023 scope)

- 32 to 81.1 DCN (range of valid results for EN 15195 per ISO 4259)

Compressed Gas Requirements

- Compressed air at 12.1 bar (175 psi)

- Compressed air (19.9-21.9% O₂) at 21.4 bar (310 psi)

- Compressed nitrogen at 3.5 bar (50 psi)

Reference Materials

- n-heptane 99.5%, octane engine grade (calibration reference material, check standard)

- Methylcyclohexane 99% (verification material)

- Reference diesel fuel (quality control sample)

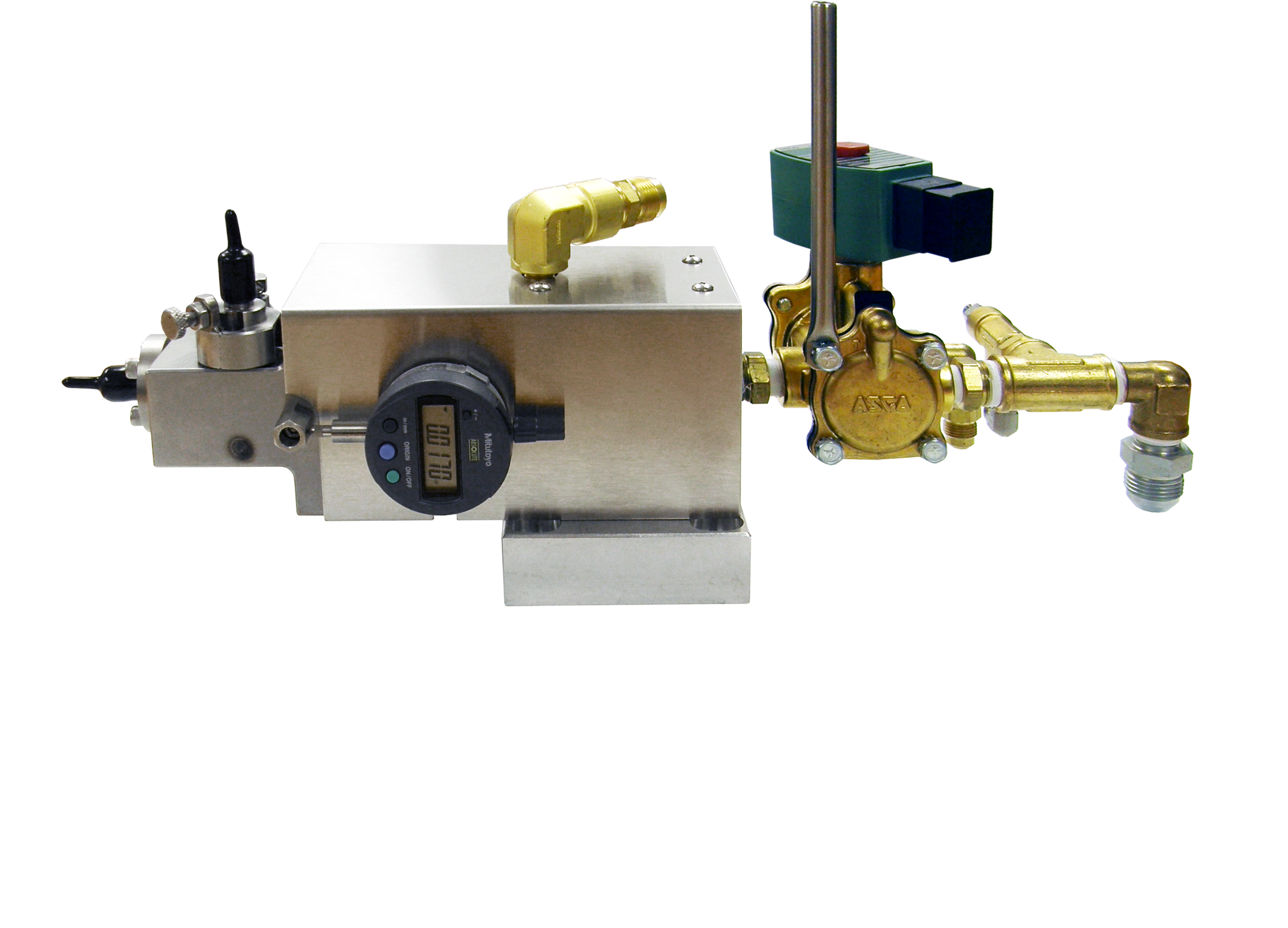

Improved Precision with HP-FIS Technology

All IQT systems utilize a modern patent pending fuel injection system. The High Precision Fuel Injection System (HP-FIS) from IQT leverages advances in injection technology to deliver the results and precision expected of today’s instruments.

- Increases the precision of results though injection management

- Upgrade capable to older IQT systems with similar design

- Reduced test variability through precision manufacturing

- Maximized performance with HP-FIS matched to whole system

Associated with Numerous Global Test Standards

Since the first commercial release of the IQT System, significant efforts have been made to ensure the instrument meets or exceeds the specifications and performance defined in industry standards. Click the link below to see all of the IQT standards associations.