Product Flexibility Built on Experience

Based on extensive technology research and product development over the past 25 years the Ignition Quality Tester (IQT™) remains the worldwide leader in CVCC testing for diesel fuel ignition delay. As the pioneer instrument for derived cetane number (DCN), the IQT excels at efficiently measuring diesel and alternative fuels in a matter of minutes using small sample volumes. Available as three product offerings from CFR Engines Canada ULC in Ottawa, Canada.

The IQT instrument (EN 15195) is the referee test method in EN 15940, the paraffinic fuels specification in Europe.

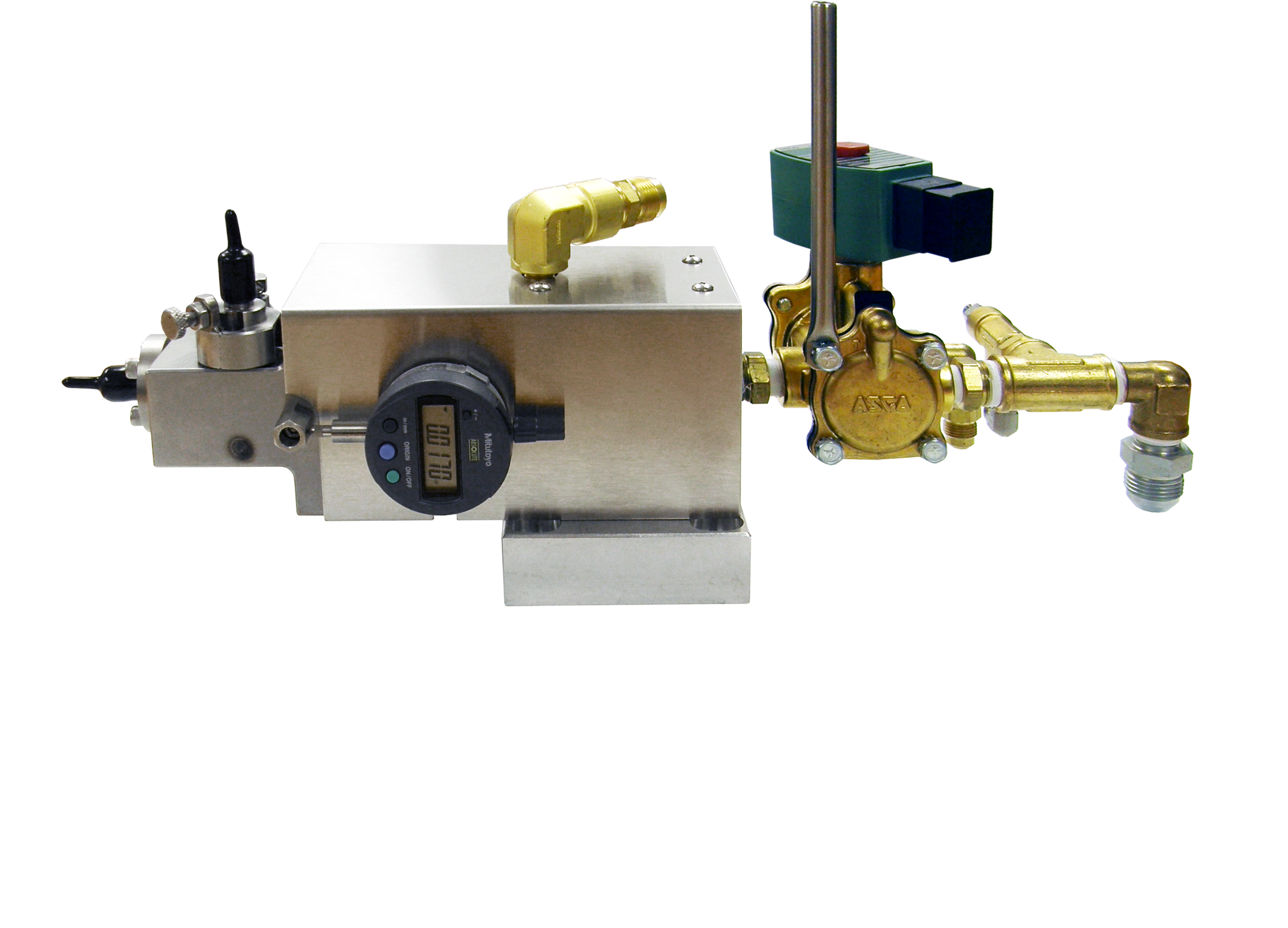

IQT TALM: This system is our automated flagship offering, equipped with the TALM Precision Package. This system offers reliable and precise ignition quality measurement with additional automation in the areas of: nozzle tip temperature control, combustion chamber pressure sensor temperature control, and coolant flow control. These automation improvements save operator time and add precision to results.

IQT LM: This system is our laboratory standard offering, with similar ignition quality results, but with more operator involvement. As the value offering without TALM automation, the IQT LM maintains a full complement of impressive IQT technology, including the high precision fuel injection system, intuitive software, and complete backup of test results.

IQT Research: This options are known around the world for adding the control and flexibility fuel researchers demand. Available as upgrades for both IQT TALM and IQT LM models, these options provide IQT users the ability to customize their tests and join the extensive community of researchers who benefit from comprehensive test parameter flexibility.

IQT®-TALM

IQT®-TALM  IQT®-LM

IQT®-LM  Research

Research  Accessories

Accessories