IQT Lab Model

Model: IQT™-LM

The Laboratory Model (LM) version of the IQT is ideally suited for those interested in a basic ignition delay testing instrument. The LM model benefits from the standard High Precision Fuel Injection System (HP-FIS), but does not include the automation and precision features of the TALM model. As the pioneer IQT model, the IQT-LM has delivered proven performance to many global users since its release in 1998.

The IQT is the specified equipment for testing fuels according to:

ASTM D6890: Standard Test Method for Determination of Ignition Delay and Derived Cetane Number (DCN) of Diesel Fuel Oils by Combustion in a Constant Volume Chamber.

EN 15195 (IP 498): Liquid petroleum products – Determination of ignition delay and derived cetane number (DCN) of middle distillate fuels by combustion in a constant volume chamber.

ASTM D6751: Standard Specification for Biodiesel Fuel Blend Stock (B100) for Middle Distillate Fuels

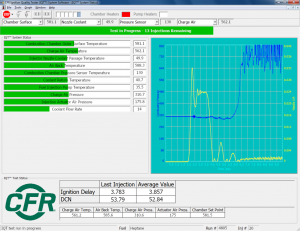

Each IQT system is supplied with a Windows 10 PC running the IQT TALM K2 software. The user interface allows improved high visibility test monitoring for viewing from anywhere in a lab environment, with the provided monitor display.

The IQT features a fully integrated data backup system which automatically backs up the entire computer system to an internal backup drive. The system’s primary drive features RAID 1 redundancy which ensures that should the computer ever have a disk drive failure, it can continue operating and the failed drive can be easily replaced.

Other Important Features

- The TALM K2 software, provides highly visible test monitoring for view at a glance assessment

- Automated calibration (recommended for use with the Extra-Large (95 mL, stainless steel) Fuel Reservoir Assembly)

- Consistent with fuel specification test methods

- Automated test procedure, quiet operation and easy to operate

- Short test time (approximately 17 minutes), high productivity

- Enhanced productivity can still be achieved with the K9 self-sealing reservoirs and cleaning/filling station which permits multiple fuel samples to be prepared for testing ahead of time through use of multiple fuel reservoirs

- Can be used with either the TALM-K7 electronic pressure regulator system (K1 is not needed) or the mechanical pressure panel

- Sensitive to cetane improver additives and small fuel quality variations

- Can measure high levels of cetane improver (3000 ppm+ 2EHN) with no negative carryover effects

- Proven ability to test highly paraffinic fuels from synthesis or hydro-treatment

- Small sample size (less than 100 mL)

- High level of reliability, rugged system, low operating and maintenance costs

- Easy access for maintenance

- Safety track record established over many years

- Proven testing capability for B100 and other biodiesel fuels from many different sources

| IQT Dimensions | 173cm (68 in) H X 106 cm (41.5 in) W X 73 cm (28.5 in) D. |

| Power Requirement | 20A, 240VAC, 50/60 Hz Protected by an Uninterruptable Power Supply (UPS) and isolation transformer |

| Air Supply | Compressed air, 20.9 % O2 ± 1.0% Regulated: 21.7 bar (310 psi) – Combustion process 12.1 bar (175 psi) – Injection process |

| Nitrogen Supply | Compressed nitrogen, industrial grade Regulated: 3.5 bar (50 psi) – Fuel feed process |

| Cooling System | Closed-circuit liquid to air cooling system |

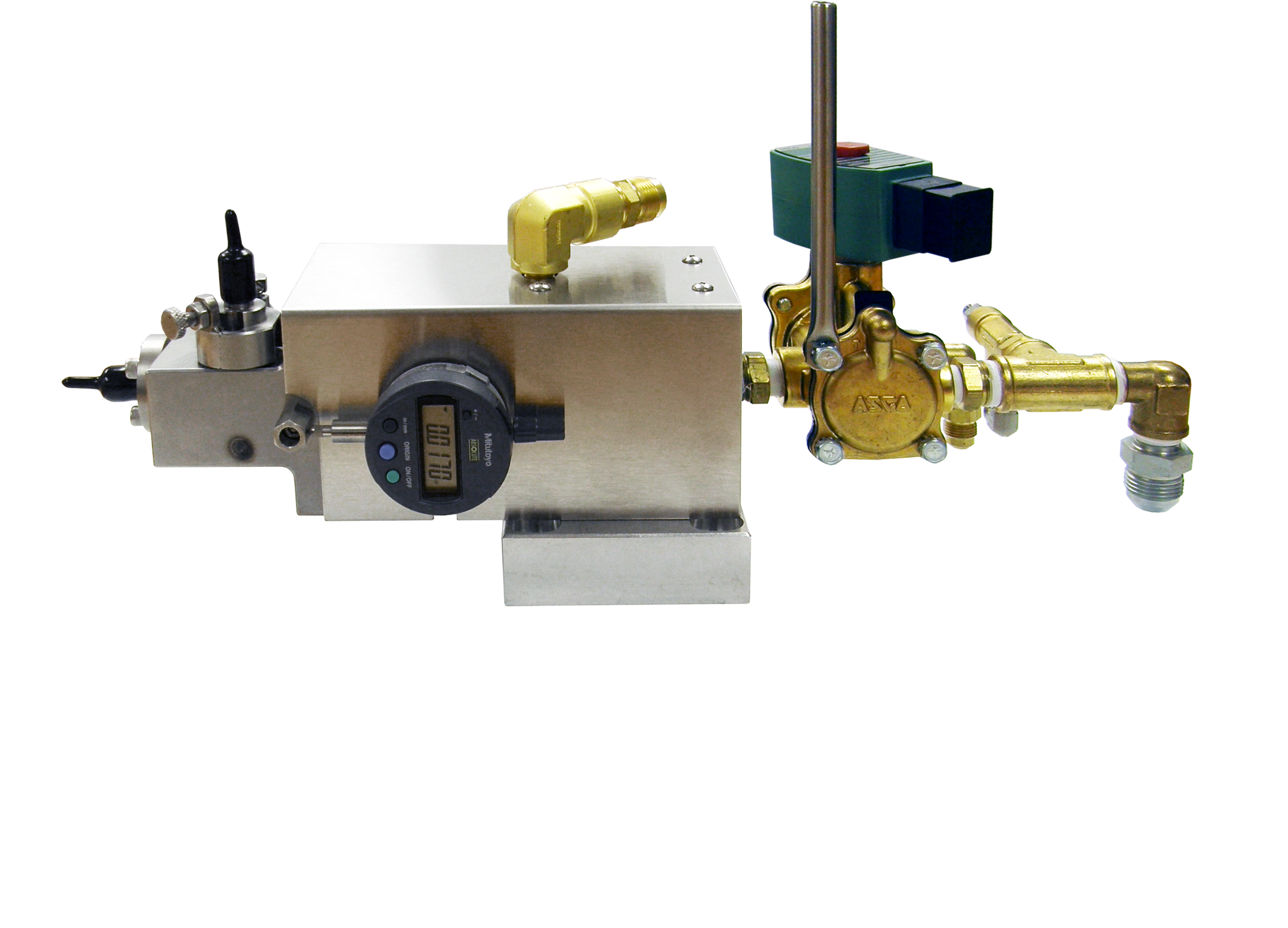

| Fuel Injection System (Patent Pending) | Pintle-type, single hole nozzle with pneumatically actuated fuel injection pump |

| Computer and Instrument Control | Rack mount computer system with automatic software backup and hot-swappable drives |

IQT®-LM

IQT®-LM